22 April 2025

Speak to one of our experts.

20 August 2024

When upgrading your vehicle’s suspension, a few persistent myths about polyurethane bushings often come to mind. Let’s set the record straight and explain why polyurethane suspension bushes are a smart choice for all types of vehicles—from everyday cars and vans to custom builds and commercial fleets.

A common misconception is that polyurethane bushes are excessively hard and uncomfortable. In truth, the firmness of these bushings is a carefully engineered feature. Extensive testing is carried out on both the suspension system and the bush itself before production begins, ensuring that the final product meets—and often exceeds—the performance of original equipment (OE) parts.

Polyurethane is extremely versatile; it can be formulated to achieve a wide range of hardness levels. This means you can opt for a firmer bush that offers precise steering response and enhanced stability for high-performance driving, or a softer version that prioritises shock absorption and comfort for everyday journeys – Our Grades Explained

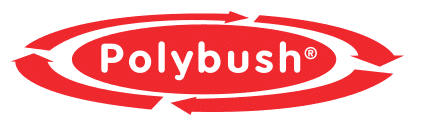

Another myth suggests that polyurethane bushings carry an unaffordable price tag. While the upfront cost may be higher than that of traditional rubber bushings, the long-term benefits make them a worthwhile investment. Polyurethane bushings are highly resistant to water, grease, ozone, and road damage, meaning they last significantly longer than their rubber counterparts.

This durability translates to fewer replacements and reduced maintenance costs over time. Whether you’re a private vehicle owner or managing a fleet, the extended lifespan and consistent performance of polyurethane bushings can lead to substantial cost savings.

Our experience includes working with organisations like West Midlands Ambulance, who were facing the issue of premature bush wear across their fleet. With traditional rubber bushes not available for individual replacement, the only option was the costly replacement of entire assemblies such as anti-roll bars and leaf springs. Recognising the long-term cost savings offered by polyurethane bushings, a switch was made that resulted in an impressive £700 reduction in parts costs per vehicle.

Many believe that installing polyurethane bushes necessitates the use of grease. On the contrary, applying grease is not only unnecessary—it’s actually discouraged. Grease can cause the bush to rotate within its housing, leading to unwanted squeaks and potentially acting as an abrasive that accelerates wear.

Instead, alternatives like tyre soap or washing-up liquid are recommended during installation. These substances provide sufficient lubrication to ease the fitting process, dry quickly, and ensure that the bush remains securely in place, thus avoiding any long-term complications.

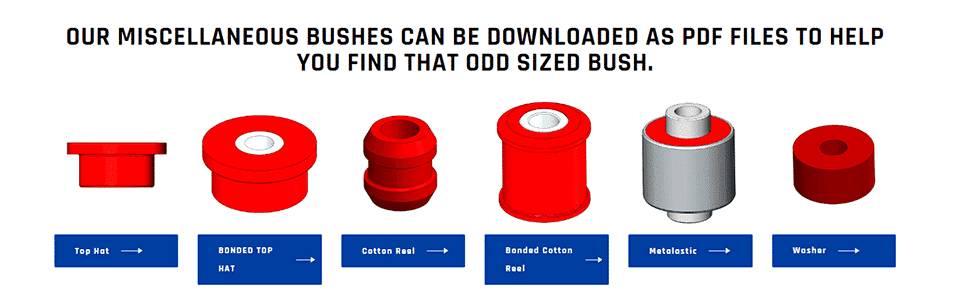

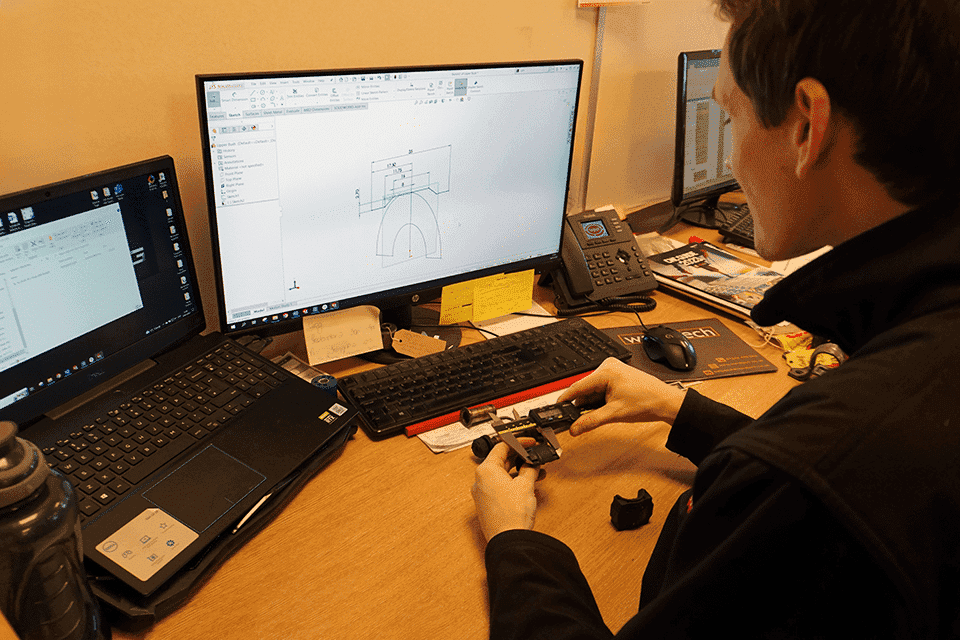

Customisation is key when it comes to optimising your vehicle’s suspension. Whether you’re restoring a classic car, fine-tuning a modern performance model, or upgrading a commercial fleet, custom polyurethane bushings can be tailored to your exact specifications. With a vast selection that covers everything from control arm bushes to subframe mounts, there’s a perfect solution available for every vehicle and driving style. Sometimes, what you require isn’t something that can be associated to a vehicle, no problem “Can’t Find What You’re Looking For”

Our expertise isn’t limited to automotive suspension upgrades. We also offer comprehensive polyurethane moulding services for a range of industries. From bespoke industrial components to specialised commercial parts, our state-of-the-art manufacturing capabilities ensure high-performance, durable products that meet your exact needs. Whether you require a small batch of custom components or a large-scale production run, we’re here to turn your vision into reality.

The myths about polyurethane suspension bushes are just that—misconceptions. With precise engineering, outstanding durability, and the flexibility to suit any vehicle or application, polyurethane bushings offer an excellent solution for enhanced performance, safety, and long-term cost savings.

Ready to upgrade your vehicle’s suspension? Contact our expert team today to discuss how our polyurethane bushings can help you achieve the perfect balance between performance and comfort.