Our Green Promise

At Polybush, we are deeply committed to sustainability and strive to minimise our environmental impact. Our primary product, polyurethane suspension bushes, unfortunately, cannot be recycled. However, we are dedicated to reducing waste and continuously seek innovative ways to repurpose our materials.

Polyurethane, while not recyclable, has significant potential for reuse. We are currently exploring alternatives such as granulation and the production of equine rehabilitation matting and children’s play area flooring. These initiatives not only help us manage waste but also contribute positively to other sectors.

Our commitment to green practices is further demonstrated by our substantial solar project. This ambitious initiative now supplies a minimum of 50% of our electricity usage. During weekends and sunny evenings over the past year, the energy we exported was sufficient to provide clean electricity for the homes of our entire workforce. This remarkable achievement underscores our dedication to renewable energy and reducing our carbon footprint.

Since the installation of our solar and Combined Heat and Power (CHP) systems, we have successfully saved approximately 159.321 tonnes of CO2. This significant reduction in greenhouse gas emissions reflects our ongoing efforts to protect the environment and operate sustainably.

At Polybush, we understand that sustainability is a journey. While polyurethane itself poses challenges, our innovative approaches and substantial investments in renewable energy demonstrate our commitment to a greener future.

Our Solar Project

Our solar project represents a major step forward in our commitment to sustainability and renewable energy. This ambitious initiative supplies at least 50% Polybush & our sister company, Bonaprene’s electricity needs, significantly reducing our reliance on non-renewable energy sources.

However, the amount of electricity consumed by Polybush’s production and offices is less than the amount we self-generate. During the summer months, Polybush as a whole, is carbon-negative.

Our journey with solar energy began in 2013 when we installed 16.5kW of solar power. This capacity grew to:

- 49kW in 2015,

- 99W in 2019,

- 149kW in 2021,

- 252kW in 2022,

- 284kW in March 2024.

In May 2024, through combined solar and CHP, we generated 52% of our electricity usage, relying on the grid for only 48% while exporting 17MWh to the grid during peak times in the evening and at weekends. In June 2024, we increased our self-generated electricity to 54.5%, reducing our dependence on the National Grid to 35.5%, and exported 15MWh to the grid during peak times.

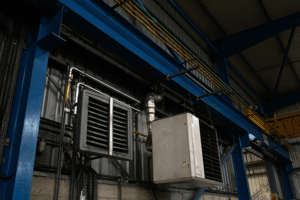

Our Combined Heat & Power (CHP) Project.

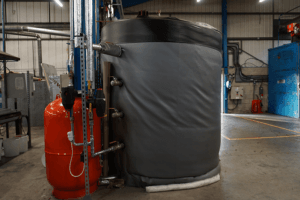

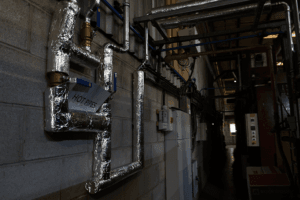

In addition to our solar power, we have installed a 20kWe Combined Heat and Power (CHP) plant in 2023, with a second unit set to be commissioned imminently. These CHP plants, while gas-fired, are more efficient than traditional power stations because they productively use the waste heat to pre-heat resin drums, to cure our finished products and to heat our sister company’s workshop.

Though Polybush is carbon negative, In May 2024, our sister company Bonaprene generated 52% of its electricity through combined solar & CHP, meaning they were only dependent on the grid for 48% of their power usage.

We also exported 17MWh to the grid during peak times in the evening and at weekends. We are currently looking to invest in batteries for both factories, to further reduce our need for grid power.

- Our CHP Container

- CHP Manifold To Push Heat To Our Ovens

- CHP Hot Pipes

- CHP Exhaust System To Heat Our Workshop

Packaging.

As of 2024, we have made a conscious effort to ensure all of our packaging is as eco-friendly as possible. This means that any plastic we use is both recyclable and made from recycled materials, reducing the demand for virgin plastics and promoting circularity. When it comes to paper and cardboard, we use only non-toxic inks, and every element of our packaging is fully compostable, ensuring that it can safely return to the environment without causing harm.

In addition, we have switched to using branded paper tape, further reducing the amount of plastic in our packaging chain. These changes reflect our ongoing commitment to sustainability, and we will continue to seek out ways to minimise our environmental impact while maintaining the high standards our customers expect.

Real Life Meaning.

At Polybush, our solar project now generates more electricity than we consume during the summer, reducing our grid dependency and even powering our employees’ homes on weekends. Since 2013, our solar and CHP systems have saved over 159 tonnes of CO2.

We’ve made all our packaging eco-friendly—recyclable plastics, compostable paper and card, and non-toxic inks. Switching to paper tape has further reduced plastic waste.

Additionally, we’re exploring ways to repurpose our polyurethane waste into useful products like equine matting and playground flooring. By choosing Polybush, you support a greener future with reduced environmental impact.